In the pursuit of cleaner air, especially in commercial and industrial settings, the introduction of high-efficiency non-partition box type V-type filters marks a significant advancement in air filtration technology. These Filters are designed to meet the stringent demands of modern ventilation and air conditioning systems, providing unparalleled performance and efficiency.

Innovative Design and Superior Filtration

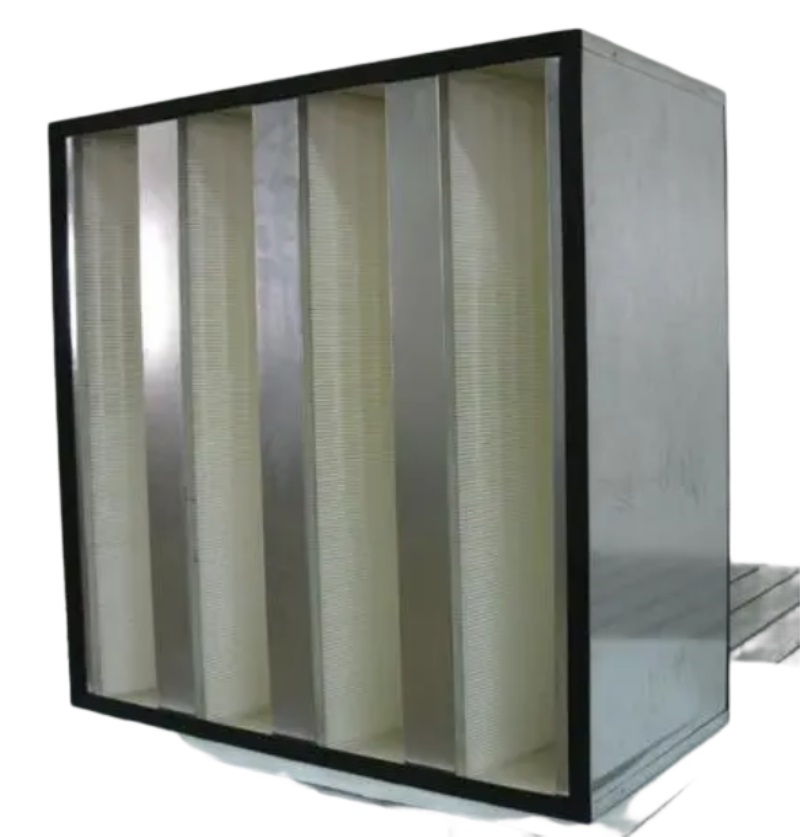

The high-efficiency non-partition box type V-type Filters are engineered with an exceptional focus on performance and reliability. Utilizing high-density filter materials, these units offer targeted filtration of tiny airborne particles, ensuring cleaner air in various environments. The filter elements are made from high-quality, moisture-proof, and flame-retardant ultra-fine glass fiber, which is pleated to maximize surface area and filtration capacity. The linear hot-melt adhesive strip partitions minimize air resistance while maintaining structural integrity, allowing for efficient airflow and reduced energy consumption.

One of the standout features of these filters is their V-shaped structure assembly. This design not only accommodates more filter materials but also enhances the overall filtration efficiency. The V-shaped pleats increase the filter media surface area, allowing for higher airflow rates without compromising on filtration quality. This innovative structure ensures that the filters can handle large volumes of air while maintaining low resistance, making them ideal for high-volume air systems.

High Air Volume and Space-Saving Solutions

These filters are designed to handle air volumes of up to 4000 cubic meters per hour, making them suitable for environments where high air volume is essential. Their ability to process large volumes of air efficiently reduces the number of filters required in a fresh air system, thereby saving installation space and reducing overall energy consumption. In existing systems, the large filter media area ensures low product resistance, which in turn reduces operating costs and extends the life of the filtration system.

Comprehensive Specifications and Applications

The high-efficiency non-partition box type V-type filters come with a range of specifications that cater to diverse needs. Available in galvanized or stainless steel frames, these filters are built to withstand harsh environments and maintain their performance over time. With a product thickness of 292mm, they are designed to fit seamlessly into existing ventilation systems.

These filters achieve filtration efficiencies of H13 and H14, as per the EN1822 standard, making them suitable for applications that require high levels of air purification. They are certified to operate continuously at temperatures up to 70°C and have a fire rating that meets the UL900 standard. The recommended final resistance is ≤600Pa, ensuring long-term reliability and performance.

Versatile Applications

The primary application of these filters is in the final filtration stage of commercial and industrial ventilation systems, clean rooms, and HVAC systems. They are particularly effective in environments where air quality is critical, such as hospitals, laboratories, and manufacturing facilities. The flame-retardant non-phosphorus polyurethane glue used as a sealant further enhances the safety and reliability of these filters.

Conclusion

The introduction of high-efficiency non-partition box type V-type filters represents a significant step forward in air filtration technology. Their innovative design, superior filtration capabilities, and ability to handle high air volumes make them an ideal solution for modern ventilation and air conditioning systems. As the demand for cleaner air continues to grow, these filters are poised to play a crucial role in ensuring healthier and safer environments across various industries.