When it comes to improving indoor air quality, few technologies are as trusted and widely used as HEPA Filters. Whether in vacuum cleaners, Air Purifiers, or HVAC systems, HEPA Filters are relied upon to remove tiny airborne particles that may trigger allergies, respiratory issues, or the spread of pathogens. But have you ever wondered—what exactly are Hepa Filters made of?

Understanding the materials behind HEPA filters helps explain their high performance and effectiveness. In this article, we’ll explore the core components, structure, and reasons why HEPA filters are so efficient at trapping particles as small as 0.3 microns.

What Does “HEPA” Mean?

Before diving into the materials, let’s define what HEPA stands for. HEPA means High-Efficiency Particulate Air. A filter must meet strict standards to be classified as HEPA, particularly in its ability to capture at least 99.97% of particles measuring 0.3 microns in diameter—the most penetrating particle size (MPPS).

The Core Material of HEPA Filters

The main material used in HEPA filters is a dense mat of randomly arranged fibers, typically composed of:

Glass microfiber (borosilicate fibers)

Synthetic polymer fibers (like polypropylene or polyester)

These fibers are extremely fine—often less than 1 micron in diameter—and are layered into a thick, pleated sheet to increase the surface area. The result is a material that allows air to pass through while capturing solid particles through mechanisms such as interception, impaction, and diffusion.

Common Materials Explained

Glass Microfiber

This is the most traditional and commonly used material in true HEPA filters. Made from borosilicate glass, these microfibers are similar to those used in laboratory glassware but are processed into ultra-thin threads.

Advantages:

Highly heat-resistant

Non-flammable

Extremely fine structure

Long-lasting filtration performance

Disadvantages:

Brittle and more delicate to handle

Not washable or reusable

Typically not biodegradable

Synthetic Polymer Fibers

Some modern HEPA filters are made with melt-blown polypropylene, polyethylene, or polyester fibers. These are often used in HEPA-type or washable filters, although some true HEPA filters also use synthetic blends.

Advantages:

More durable and flexible

Water-resistant (some are washable)

Easier to shape and mold

Lightweight and affordable

Disadvantages:

May have lower heat resistance

Less effective in extremely high-performance applications compared to glass microfiber

Composite Materials

In some high-end applications, manufacturers combine glass fibers and synthetic fibers to enhance durability, filtration efficiency, or mechanical strength. These composite HEPA filters are often found in industrial or medical-grade equipment where higher pressure and longer life cycles are required.

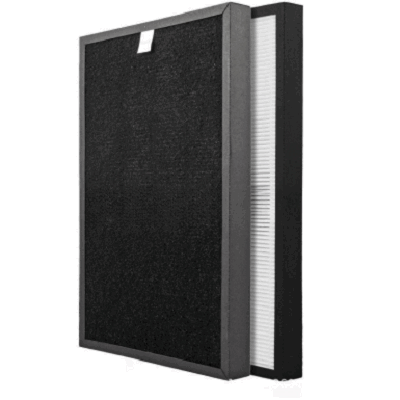

HEPA Filter Structure and Design

To maximize efficiency, the filter media is usually pleated into a series of folds, which greatly increases the total surface area within a compact space. The pleats are then supported by:

Aluminum separators or mesh (in industrial filters)

Plastic frames or cardboard (in home devices)

Rubber or foam gaskets to prevent air leakage around the edges

Some filters also feature pre-filters made from foam or coarse mesh to trap larger particles like dust or hair, which helps protect the delicate HEPA media and extend its lifespan.

Why the Material Matters

The material composition of a HEPA filter directly impacts its performance, durability, cost, and specific application. For instance:

Glass microfiber filters are ideal for hospital and laboratory use where precision is critical.

Synthetic HEPA filters are better for consumer-grade air purifiers, especially where reusability or cost efficiency is a concern.

Composite filters are often used in commercial or heavy-duty HVAC systems that operate continuously.

Are All HEPA Filters the Same?

No. While all true HEPA filters meet the same efficiency standard (99.97% at 0.3 microns), the materials used, durability, and maintenance needs can vary widely. Some cheaper “HEPA-like” filters may not meet the full standard but use similar fiber materials. Always look for certifications such as EN1822 or U.S. DOE Standard MIL-STD-282 to verify a filter’s quality.

Conclusion

HEPA filters are primarily made from tightly woven mats of glass microfiber or synthetic polymer fibers. These materials, whether used alone or in combination, are engineered to trap microscopic particles with high efficiency while allowing clean air to pass through. Understanding the materials that make up HEPA filters can help consumers and businesses choose the right type for their specific needs—whether it's for allergy relief at home, cleanroom conditions in a lab, or high-volume air purification in an industrial setting.

As air quality becomes a growing concern worldwide, the demand for high-performance filtration materials like those found in HEPA filters continues to rise. Choosing the right material is key to maintaining cleaner, healthier environments—one filtered breath at a time.