When it comes to air purification, the performance of a HEPA Filter depends heavily on the composition and design of its material. Among the many factors that determine efficiency, the thickness of the Hepa Filter material plays one of the most critical roles. The right thickness ensures a balance between clean air delivery and smooth airflow, helping maintain both filtration quality and system energy efficiency.

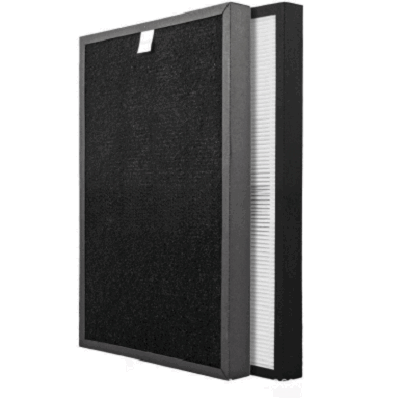

HEPA filter material is usually made from ultra-fine glass fibers or melt-blown polypropylene fibers. These fibers form a dense web capable of capturing particles such as dust, pollen, bacteria, and smoke. The denser and thicker the material, the more particles it can trap as air passes through. Each additional layer increases the likelihood of capturing fine contaminants, making thicker filters more effective at removing small airborne particles.

However, thicker material also increases airflow resistance. As the filter becomes denser, the air has to push harder to pass through it, leading to higher pressure drop and energy consumption. This can reduce the efficiency of the Air purifier or HVAC system, as the motor must work more to maintain the same air output. Therefore, while a thicker HEPA filter improves filtration efficiency, it can also compromise airflow performance if not properly optimized.

On the other hand, thinner HEPA filter material allows air to move more freely, resulting in lower resistance and improved energy efficiency. Yet, a thinner layer may fail to capture the smallest particles effectively, lowering the filtration grade. The challenge for designers is to find the right balance—enough thickness to trap fine contaminants but not so much that it restricts airflow.

In modern filter manufacturing, advanced materials and multilayer structures help achieve this balance. Some HEPA filter materials incorporate nanofiber coatings or gradient layering technology, which allows high-efficiency filtration with minimal airflow resistance. This innovation ensures that Air Purifiers and HVAC systems can deliver both strong filtration performance and stable airflow over time.

The ideal thickness of HEPA filter material varies depending on the application. Home air purifiers usually prefer moderate thickness for quiet, efficient performance. Industrial and cleanroom systems, where air purity standards are much stricter, use thicker or multi-layer materials to ensure the highest filtration accuracy. Regardless of the use case, maintaining the right material thickness is essential to achieving reliable, long-term air quality performance.

In conclusion, the thickness of HEPA filter material has a direct impact on both airflow and filtration efficiency. Too thin, and harmful particles escape; too thick, and energy efficiency declines. The key is balance—choosing a material design that captures contaminants effectively while maintaining optimal airflow. As technology advances, modern HEPA filter materials continue to evolve, providing cleaner air with greater efficiency for homes, industries, and medical environments alike.