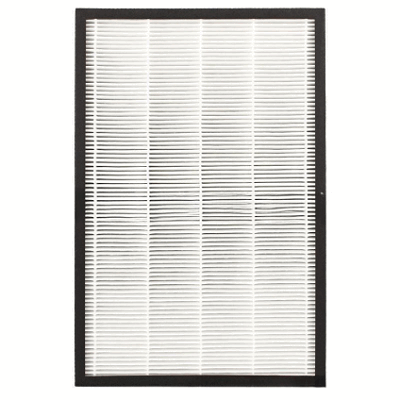

The performance of a HEPA Filter depends greatly on the quality and structure of its filtration layer.Among all materials used in modern air purification,melt-blown nonwoven fabric plays an essential role in achieving high filtration efficiency.Known for its fine fiber diameter and dense structure,melt-blown nonwoven serves as the core filtration layer that determines how effectively a Hepa Filter captures microscopic particles while maintaining smooth airflow.

Melt-blown nonwoven material is produced through a high-temperature extrusion process in which polymer,often polypropylene(PP),is melted and blown into ultra-fine fibers.These fibers interlace randomly to form a porous yet compact web.The microscopic gaps between fibers create an electrostatic field that helps trap dust,pollen,bacteria,and even viruses.Because of this unique fiber structure,melt-blown nonwoven fabric becomes the heart of HEPA filter materials,providing both mechanical and electrostatic filtration performance.

The efficiency of HEPA Filters depends not only on the density of the material but also on the uniformity of the melt-blown layer.A high-quality melt-blown nonwoven ensures consistent fiber distribution and pore size,which allows the filter to achieve superior particle capture without significantly restricting airflow.This balance between filtration precision and air permeability is what makes melt-blown fabric indispensable in Air Purifier Filters,HVAC systems,and cleanroom filtration units.

If the melt-blown layer is poorly made or too thin,the HEPA filter’s overall performance drops dramatically.Air can pass through without sufficient particle capture,leading to reduced air quality and system inefficiency.Conversely,if the material is overly dense,airflow resistance increases,forcing the fan or motor to consume more energy.Therefore,manufacturers must carefully control the melt-blown production process—fiber diameter,web uniformity,and electrostatic treatment all play critical roles in achieving the right balance.

Advances in melt-blown nonwoven technology have led to significant improvements in HEPA filter material performance.Modern production methods allow for ultra-fine fibers with diameters as small as one micron,providing exceptional filtration while maintaining low resistance.Some manufacturers also apply electret charging to enhance the electrostatic attraction of fibers,allowing them to capture even smaller particles without adding extra thickness.

In industries such as healthcare,electronics,and environmental control,melt-blown nonwoven HEPA materials are indispensable.They ensure that air handling systems maintain clean,particle-free environments critical to safety and product quality.For consumers,the same technology delivers cleaner indoor air through household purifiers and automotive cabin filters.

In summary,melt-blown nonwoven fabric is the backbone of HEPA filter material efficiency.Its unique fiber structure,electrostatic properties,and controlled density make it the key to achieving both high filtration performance and energy-efficient airflow.As global demand for cleaner air continues to rise,innovations in melt-blown nonwoven technology will remain vital to the future of air filtration systems.