Choosing between fiberglass HEPA Filter material and synthetic Hepa Filter material is one of the most important decisions faced by buyers in the air filtration industry.While both materials are widely used,their performance characteristics,durability,and application suitability differ significantly.Understanding these differences helps purchasers select the right HEPA Filter material for their specific operational needs.

Fiberglass HEPA filter material has been used for decades and is considered the traditional and most proven solution for high-efficiency filtration.It is made from ultra-fine glass fibers bonded into a dense,nonwoven structure.This structure creates a complex network of airflow paths,allowing particles to be captured through mechanical filtration mechanisms rather than relying on electrostatic attraction.As a result,filtration efficiency remains stable throughout the service life of the filter.

Synthetic HEPA filter material,on the other hand,is typically produced from polymer-based fibers such as polypropylene or polyester.These materials are often lighter and more flexible than fiberglass.Many synthetic HEPA filter materials enhance filtration efficiency by applying an electrostatic charge to the fibers,which attracts and captures airborne particles.While this approach can be effective in the short term,efficiency may decline as the charge dissipates over time.

One of the most significant differences between fiberglass and synthetic HEPA filter material is long-term performance stability.Fiberglass media maintains consistent efficiency even under continuous airflow and challenging environmental conditions.This makes it the preferred choice for medical grade HEPA filter material,where reliability is critical.Synthetic materials may be suitable for consumer or light industrial applications,but their performance stability must be carefully evaluated for critical environments.

Airflow resistance,or pressure drop,is another key consideration.Synthetic HEPA filter material often offers lower initial pressure drop,which can reduce energy consumption in HVAC systems.However,as dust accumulates and electrostatic charge weakens,pressure drop can increase unpredictably.Fiberglass HEPA filter material generally has a higher initial resistance but offers more predictable performance over time,which is valued in engineered systems.

Durability and environmental resistance also differ between the two materials.Fiberglass HEPA filter material performs well in high-temperature and high-humidity environments.It is resistant to moisture absorption and chemical degradation,making it suitable for pharmaceutical manufacturing,laboratories,and hospital isolation rooms.Synthetic materials may deform or lose efficiency when exposed to extreme conditions,limiting their use in certain applications.

From a safety and compliance perspective,fiberglass HEPA filter material is widely accepted in international standards governing medical and cleanroom filtration.Many medical grade HEPA filter material specifications explicitly reference fiberglass media due to its proven performance history.Reputable HEPA filter material manufacturers design fiberglass-based products to meet stringent regulatory requirements,including uniform efficiency testing and leak detection.

Cost considerations also play a role in material selection.Synthetic HEPA filter material is often less expensive to produce,which can make it attractive for high-volume,cost-sensitive markets.Fiberglass HEPA filter material typically has a higher upfront cost due to raw material quality and manufacturing complexity.However,when evaluated over the full lifecycle—including efficiency stability,replacement frequency,and energy costs—fiberglass often provides better overall value for critical applications.

Sustainability is becoming an increasingly important factor in purchasing decisions.Synthetic materials may offer advantages in terms of recyclability and lower material weight,while fiberglass HEPA filter material offers longer service life,reducing waste from frequent replacements.Leading HEPA filter material manufacturers are actively improving both material types to address environmental concerns while maintaining performance.

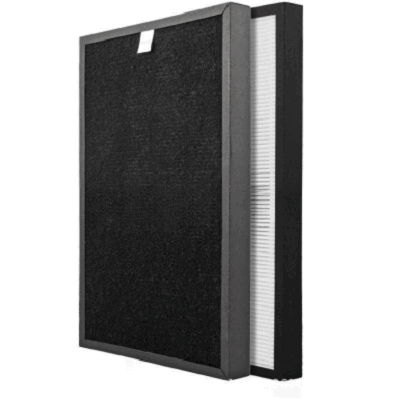

In practical terms,the choice between fiberglass and synthetic HEPA filter material depends on the application.For hospitals,pharmaceutical cleanrooms,and laboratories,fiberglass remains the preferred solution due to its stable efficiency and compliance with medical grade HEPA filter material standards.For residential Air Purifiers or less demanding industrial environments,synthetic materials may offer an acceptable balance of performance and cost.

Ultimately,selecting the right HEPA filter material requires a clear understanding of performance requirements,operating conditions,and regulatory expectations.Working closely with an experienced HEPA filter material manufacturer ensures that the chosen solution—whether fiberglass or synthetic—meets both technical and commercial objectives.For applications where reliability and safety are paramount,medical grade HEPA filter material based on fiberglass technology continues to set the industry standard.